Youngs Welding

Equipment

We’re Equipped For Your Project

Our fabrication shop is equipped to take your concept from raw material to completed product. We combine the latest technology with experienced craftsmen and reliable ironworker equipment to produce the highest quality parts and products efficiently and to your schedule.

Partial Equipment List

- Custom Powder Coat Facility capable of accepting parts up to 5' x 9' x 40' and weighing up to 3,000 lbs. Surfaces are prepared for coating by acid cleaning and etching or sandblasting, as required. In addition, our system has an in-line shot blaster.

- BySmart 10,000-watt fiber laser - Steel up to 1.18", Stainless Steel 1.18", Aluminum 1.18", Copper 0.47 in., Brass 0.59. Max sheet size 160"x80"

- Tanaka 4,000-watt laser accurate to ± 0.004" over 40" with a production cut capacity of 3/4" plate measuring up to 120" x 44'

- Messer Cutting System: can cut 3" Carbon Steel, 1 3/4" Stainless Steel, 1 1/2" Aluminum. 400amp Hypertherm cutting Torch

- Peddinghaus three-spindle drill line capable of working on 30" W x 16" H by 10,000-lb max

- Pullmax 16-axis press brake, 12' by 350 ton, accurate to ± 0.004"

- Press Brake: 7-axis, 8' by 120 ton, accurate to ± 0.004"

- Press Brake: 250-ton

- Angle Iron Roll: 5" x 5" x 1/2"

- Plate Shear capable of handling 3/8" x 12' sheets of carbon steel

- Angle Shear and Punch Machine: 6" x 6" x 5/8" x 40'.

- Saws from 60 to 90 degrees capable of cuts up to 38" x 18"

- Plate Rolls designed for materials from 10' x 3/4" thick

- Forming: up to 120 tons of capacity

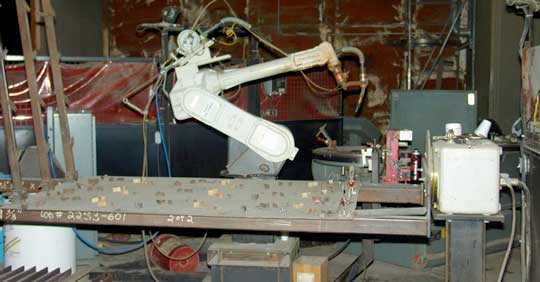

- Welders: All types of welding processes, including robotic welding cells. Cell size 80’ long, 14’ high, 8’ reach.

- Material Handling: two 30,000-lb bridge cranes; 50,000-lb Link Belt Mobile; 36,000-lb P&H mobile; 22,500-lb forklift; two 13,000-lb forklifts; several 80,000 GVW tractor trailers; 70,000-lb double-drop 70' stretch trailer